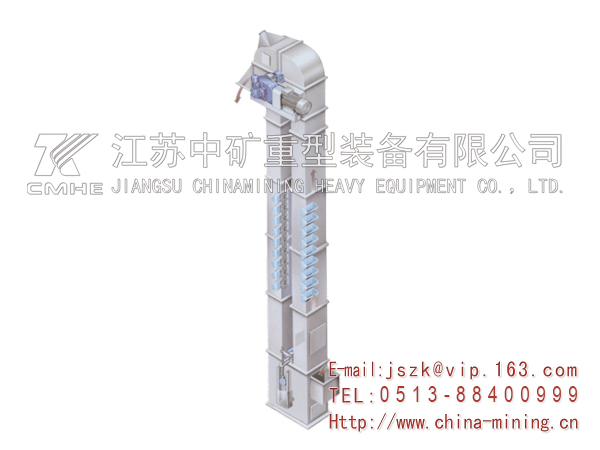

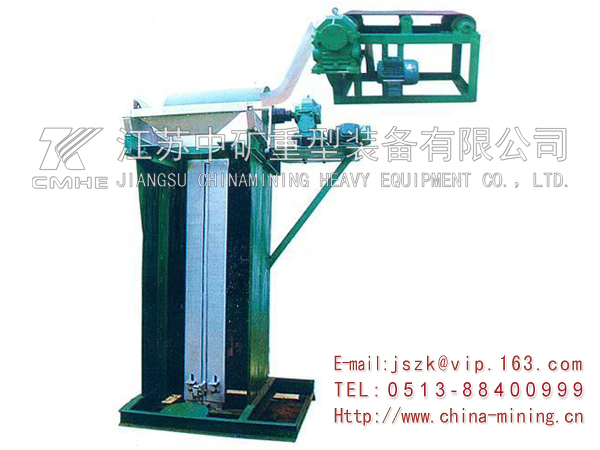

钢丝胶带斗式提升机(TGD胶带提升机)

周先生 13906278080 丁宝勤 13906276368

电话:0513-88400999 传真:0513-88400998 邮箱:jszk@vip.163.com

产品概述

钢丝胶带斗式提升机(TGD胶带提升机)具有输送量大、体积小、功耗低、运行平稳可靠、使用寿命长等特点。钢丝胶带斗式提升机适用于干散粉状物料或物料垂直提升,广泛应于建材、冶金、化工、粮食、电力等行业散状物料提升系统,是新型干法水泥厂窑尾入窑生料,生料均化库、水泥库入库物料取代国外同规格产品的替换品。

I .Brief description

TGD Steel Wire Bucket elvator is a new product developed by CMHE that combined domestic production and use with foreign new technologies. This product is featured by large conveying capacity, small dimension, low power consumption, stable working and long service life. It is used for vertically lifting dry powdery and particulate materials in many industries, such as, building material, metallurgy, chemical, grain and power, etc. It is a good substitute for exported product of the same specification to be used for raw material charge at the kiln tail of the new dry process cement plant, raw - material homogenizing silo and cement silo.

工作原理

TGD型钢丝绳芯胶带斗式提升机牵引构件采用高强度钢丝绳芯橡胶带,克服了链条啮合驱动产生动载荷,较链条更轻便,工作平稳,能以更快的运动速度达到更高的生产率,在同样的生产条件下,胶带因其工作速度高和自重较轻,可使物料线荷载和牵引构件的线载荷减少,从而减少整机的尺寸和自重。

同时由于胶带具有良好弹性和柔韧性,在料斗进行装载时有减振作用,由于采用了高强度钢丝绳芯胶带,可使提升机的提升高度和输送 提高,因而TGD型钢丝绳芯胶带斗式提升机具有良好发展前景。

性能特点

1、提升高度高,单机可达到100m。

2、输送能力大,可达到950m3/h。

3、物料温度可达120℃。

4、料斗间排列紧密,连续提取,连续卸料。

5、使用寿命长,运行可靠性好,无故障时间可超过3万小时。

6、功耗低,使用成本低。

7、操作维修方便,易损件少,维护费用比一般斗式提升减少80%以上。

8、结构精度高,强度大,外观美观。

技术参数

TGD型高效斗式提升机技术参数

机 型

| 斗 宽 | 斗 容 L | 带 速 M/s | 提升能力Q m³/h | 减速 机速 比 | |||||

斗距t(mm) | ||||||||||

360 | 400 | 440 | 480 | 510 | 550 | |||||

TGD250浅斗 | 250 | 5.84 | 1.5 | 70 | 63 | 57 | 52 | 49 | 45 | 31.5 |

TGD250深斗 | 8.03 | 96 | 86 | 78 | 72 | 68 | 63 | 31.5 | ||

TGD315浅斗 | 315 | 7.37 | 1.5 | 88 | 79 | 72 | 66 | 62 | 57 | 31.5 |

TGD315深斗 | 10.13 | 121 | 109 | 99 | 91 | 85 | 79 | 31.5 | ||

TGD400浅斗 | 400 | 11.9 | 1.52 | 144 | 130 | 117 | 108 | 102 | 94 | 40 |

TGD400深斗 | 16.11 | 195 | 176 | 160 | 146 | 138 | 128 | 40 | ||

TGD500浅斗 | 500 | 18.65 | 1.52 | 226 | 204 | 185 | 170 | 160 | 148 | 40 |

TGD500深斗 | 25.29 |

| 276 | 251 | 230 | 217 | 201 | 40 | ||

TGD630浅斗 | 630 | 29.39 | 1.68 |

| 355 | 323 | 296 | 278 | 258 | 45 |

TGD630深斗 | 39.96 |

|

| 439 | 402 | 379 | 351 | 45 | ||

TGD800浅斗 | 800 | 33.21 | 1.68 | 446 | 401 | 365 | 334 | 315 | 292 | 45 |

TGD800深斗 | 43.74 |

| 529 | 480 | 440 | 414 | 384 | 45 | ||

TGD1000浅斗 | 1000 | 50.35 | 1.89 |

| 685 | 622 | 570 | 537 | 498 | 50 |

TGD1000深斗 | 64.15 |

| 872 | 793 | 727 | 684 | 634 | 50 | ||

TGD1250浅斗 | 1250 | 62.93 | 1.89 |

| 856 | 777 | 712 | 671 | 622 | 50 |

TGD1250深斗 | 80.18 |

| 1091 | 991 | 908 | 855 | 792 | 50 | ||

注:

1、表格中的输送能力相应于100%的装填量(装水)

2、合理料斗填充率:75%左右

品质保证

1、驱动装置交轴硬齿面减速机与提升机主轴直联,结构紧凑、合理、可靠,与减速机间采用滚力偶合器,实现柔性传动,并实现对电机的过载保护;减速机上配备逆止装置,防止倒转;配有辅转电机,方便检修。

2、采用防撕裂强度高的钢丝绳胶带,配有胶带头和料斗固定件,使胶带在运行中不脱开、不撕(断)裂,提高了胶带的使用寿命;设计合理,并有不同型式排列,确保物料连续提升机卸出。

3、头部滚筒设计采用自动对中装置,滚筒包前采用高性能橡胶,使用寿命长,摩擦力大。

4、中部机壳采用双通道优代设计,避免相对高速运行的胶带带来的涡流干扰,并设有加强角钢。

5、尾部滚筒采用轮辐式设计,有效排出附着在胶带上的物料,提高胶带的使用寿命;尾部采用齿轮条重力张紧装置;同步调节尾部滚筒行程。尾部滚筒采用自动对中设计,并附设皮带防跑偏装置和料位控制仪、速度检测仪。

Quality Assurance

1. The drive has a reducer of rectangular axis and hard-toothed surface linked with the elevator shaft, which is well and reasonably structured. Fluid coupling is used between the motor and reducer, which makes flexible transmission po accessory motor, which makes check and repair convenient.

2_The product uses specially designed tear—proof high-strength steal wire rubber belt, together with specially designed belt connector and bucket fixers, which makes it possible for the belt not to come off or tear apart, and increases the service life. The elevators of the same model are able to have different conveying capacities by changing the buckets* distances so as to meet different design requirements.

The head roller has an automatic centering device. The roller* s wrapping rubber has high performance, long service life and great friction force.

The middle casing has two passages, which can avoid the vortex interference caused by the fast running belt. Also, it uses angle stiffeners. ,

The tail roller is spoke type, which can cast off the material stuck to the belt, and increase the belt* s service life. The tail has a double-arm co-axial gravity tensioning device, which can adjust the tail roller synchronously. The tail roller has an automatic centering device, belt deviation device, level control indicator and velometor. The tail structure is designed by CMHE alone. (Counterfeiting will be prosecuted.)

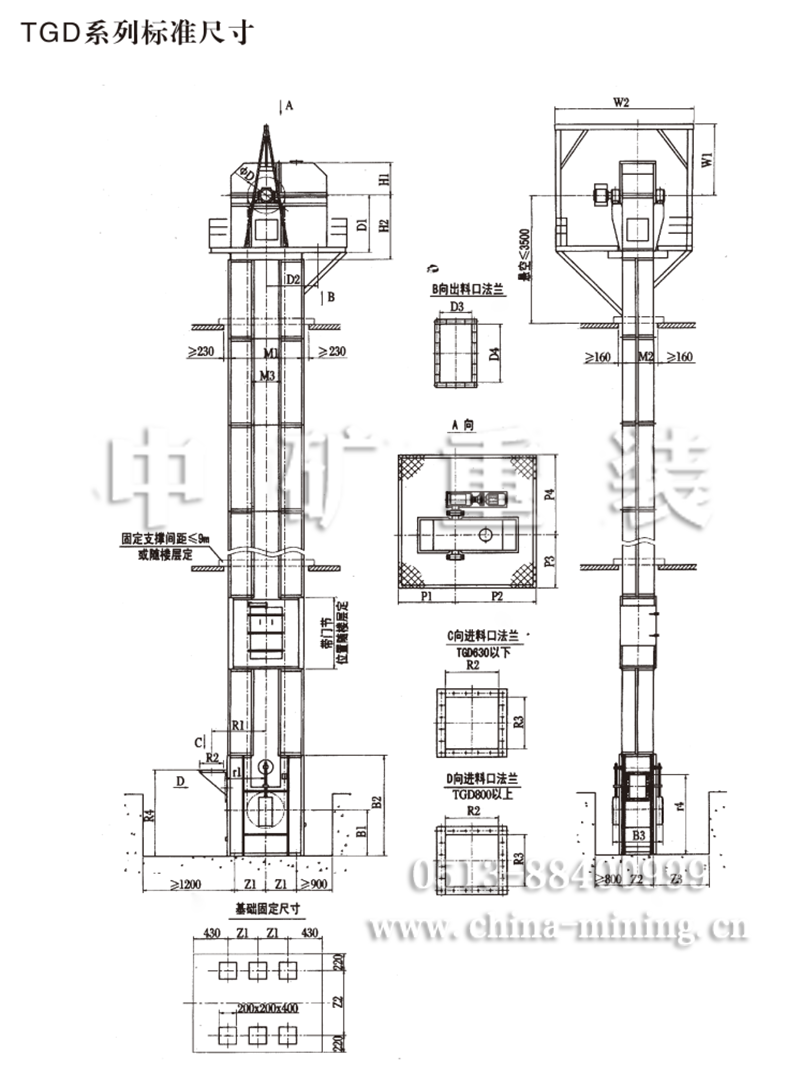

TGD系列标准尺寸

TGD斗式提升机尾部

标准尺寸

机型 |

| TGD315 | TGD400 | TGD500 | TGD630 | TGD800 | TGD1000 | TGD1250 | TGD1400 | TGD1600 |

滚筒直径 | D | 630 | 800 | 1000 | 1250 | |||||

上部机壳 | H1 | 912 | 905 | 1095 | 1192 | 1192 | 1385 | 1385 | 1385 | 1385 |

H2 | 1120 | 1350 | 1400 | 1600 | 1600 | 1800 | 1800 | 1800 | 1800 | |

卸料口 | D2 | 950 | 1150 | 1250 | 1400 | 1500 | 1700 | 1950 | 2100 | 2300 |

D3 | 350 | 400 | 500 | 500 | 630 | 630 | 630 | 630 | 630 | |

D4 | 560 | 640 | 750 | 900 | 1100 | 1300 | 1550 | 1700 | 1900 | |

平台 | P1 | 1100 | 1300 | 1300 | 1400 | 1500 | 1650 | 1650 | 1650 | 1650 |

P2 | 2000 | 2000 | 2100 | 2500 | 2500 | 2850 | 2850 | 2850 | 2850 | |

P3 | 1500 | 1500 | 1600 | 1800 | 1800 | 1800 | 1930 | 2000 | 3100 | |

P4 | 2000 | 2200 | 2100 | 2400 | 2800 | 2950 | 3100 | 3200 | 3250 | |

P5 | 897 | 1107 | 1137 | 1337 | 714 | 618 | 618 | 618 | 618 | |

维修架 | W1 | 1727 | 1727 | 1805 | 1825 | 2424 | 2875 | 2875 | 2875 | 2875 |

W2 | 3400 | 3600 | 3600 | 4100 | 4500 | 4650 | 4930 | 5100 | 6250 | |

中间机壳 | M1 | 435 | 500 | 530 | 590 | 650 | 700 | 700 | 700 | 700 |

M2 | 480 | 600 | 640 | 770 | 700 | 1000 | 1000 | 1000 | 1000 | |

进料口 | R1 | 950 | 1150 | 1250 | 1400 | 1500 | 1700 | 1700 | 1700 | 1700 |

R2 | 300 | 400 | 500 | 500 | 630 | 630 | 630 | 630 | 630 | |

R3 | 300 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | |

R4 | 1600 | 1800 | 1900 | 1950 | 2000 | 2600 | 2600 | 2600 | 2600 | |

下部机壳 | B1 | 830 | 950 | 1050 | 1100 | 1100 | 1350 | 1350 | 1350 | 1350 |

B2 | 1800 | 2150 | 2250 | 2350 | 2350 | 2800 | 2800 | 2800 | 2800 | |

B3 | 1100 | 1200 | 1300 | 1450 | 1550 | 1850 | 2100 | 2250 | 2450 | |

基础坑尺寸 | Z1 | 560 | 600 | 700 | 850 | 900 | 700 | 700 | 700 | 700 |

Z2 | 630 | 730 | 840 | 990 | 1200 | 1420 | 1670 | 1820 | 2020 | |

Z3 | 1200 | 1300 | 1400 | 1550 | 1650 | 1950 | 2200 | 2350 | 2550 | |

订货须知

用户在订货时请提供下列数据

设备名称: |

| 粒数: | mm |

输送物料: |

| 容重: | t/m³ |

输送能力: |

| 温度: | ℃ |

提升高度: | m | 水分 | % |

运转时间: | H/d | 特性 | 磨损性、粘型、腐蚀性 |

使用场所: | 室外、室内 |