水泥储存库

丁宝勤 13906276368(技术)

电话:0513-88400999 传真:0513-88400998 邮箱:jszk@vip.163.com

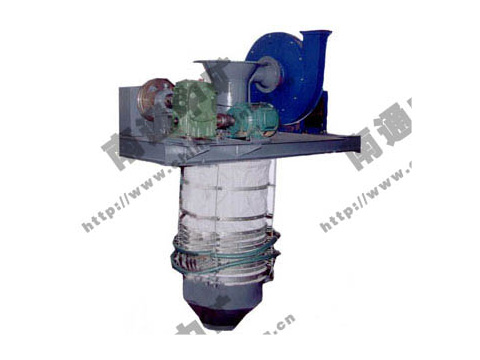

一、概述

水泥储存库是在库底中心位置设一锥形混合室,以降低库内的卸料压力,消除漏斗流。混合室 设8~12个进料孔,在混合室和库壁之间的环形区设有8~12个充气区,卸料时轮流向相对的环形小 区充气,使部分水泥流向中心混合室。在自上而下的流动过程中,切割水平料层而产生重力混合作 用,进入混合室后又因混合室内的连续充气搅拌而进一步均化。这种库的均化值可达5~9。电耗 0.15~0. 30kwh / t.

I .Brief introduction

Cement storage silo has a cone mixing room in the center of bottom silo to reduce discharge pressure in silo and eliminate funnel flow. Mixing room is arranged 8 to 12 inlet holes. There is 8 to 12 aerating zones between mixing room and silo wall. Aerate small circular zone in turn when discharging. Make some cement flow toward central mixing room. Mix them with gravity because of cutting horizontal layer during flowing from up to down. Homogenize them again because of continuous aerating and mixing room. The homogenized valve can meet 5 to 9 and power consumption is 0.15 to 0.30KWh/t.

二、示意图

.jpg)

Φ 12米储存库技术参数(Technical parameter of Φ12m storage silo)

序号(NO.) | 名称及规格Name & specification | 数量(Qty.) | 单位 Unit |

1 | 气箱式脉冲收尘器PPC32-4风机:9-26N08D Air case and pulse dust filter PPCS32-4 Fan:9-26 N0.8D | 1 | 套 set |

2 | 库顶进料系统Inlet system of top silo | 1 | 套 set |

3 | 库底、库内充气系统Aerating system of bottom silo and in silo | 1 | 套 set |

4 | 双六咀空气分配阀2-(|> 500 Double 6-spouts air distributor 2-0500 | 1 | 台 set |

5 | 库底卸料阀系统Discharge valve system of bottom silo | 2 | 套 set |

6 | 库底散装机ZSQ300/600 Bulk loader of bottom silo ZSQ300/600 | 1 | 台 set |

7 | 罗茨风机MJL200b风量:15.4m3/min风压:68.4KPa功率:37KW Roots fan MJL200b Volume: 15.4m3/min Pressure:68.4KPa Power:37KW | 1 | 台 set |

上一页:空气输送斜槽

下一页: