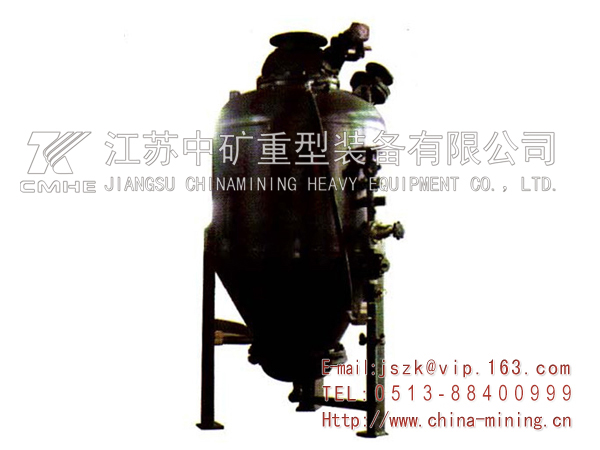

PPCA/S气箱脉冲袋收尘器

丁宝勤 13906276368(技术)

电话:0513-88400999 传真:0513-88400998 邮箱:jszk@vip.163.com

一、概述

气箱式脉冲袋收尘器是从美国富乐公司引进的具有先进水平的高效袋收尘器。它综合分室反吹和喷吹脉冲清灰各类袋收尘器的优点,克服了分室反吹清灰强度不够,喷吹脉冲清灰和过滤同时进行的缺点,因而扩大了袋收尘器的应用范围,由于这种类型的收尘器的结构有其特点,所以提高了收尘效率,延长了滤袋的使用寿命。

PPCA/S气箱脉冲袋收尘器可广泛用于水泥厂的破碎、包装、库顶、熟料冷却机和各种磨机等收尘如用于煤磨收尘,要增设防燃防暴措施。收尘器结构也要相应的改变,还适合于含尘浓度特高气体的收尘,如带O-SEPA选粉机的粉磨系统,气体含尘浓度高达1000g/m3 (标)以上,采用本系列收尘器收尘,可不设置旋风收尘器作一级收尘。除用于水泥工业外,也实用于冶金、化工、机械和民用锅炉等废气的收尘。本系列收尘器滤袋的材质,一般采用涤纶针刺毡,允许连续使用温度小于120度。如滤袋采用芳纶针刺毡,其允许使用温度可达210度。如处理的废气温度高于上述滤料的允许温度,废气进入收尘器之前应采取降温措施。

PPCA/S气箱脉冲袋收尘器为户外式由不同室数和每室的不同袋数,组成多种不同规格。每室的袋数有32、64、96、128袋四种,全系列共有33种规格,滤袋直径均为130mm,滤袋长度有2450mm和3060m两种。本系列收尘器能负压或正压操作,其本体结构无任何改变,其收尘效率可达99.9%以上,净化后气体的汗尘浓度小于100mg/Nm3(标),本系列收尘器的主要技术性能分别见附表。本系列收尘器如用于寒冷地区,当室外采暖计算温度<-25度时,需要增充加热装置,收尘器的壳体也要增设保温层。

Ⅰ.Brief introduction

Air case pulse (Plenum Pulse bag filter is introduced the technology from USA Fuller Company) is an advanced level and high efficiency dust filter. It has the advantages of divided chamber and spraying pulse, overcome divided chamber and spraying strength is not enough, spraying pulse dust and filtering at the same time. So it enlarges application range of bag filter. It can improve the efficiency of dust and prolong the life of filtering bag.

This series product is widely used in crushing, packing, clinker cooler and all kinds of mill to collecting dust in cement factory. If it is used in collecting dust of coal mill, it should add fireproof and flameproof measurement. It cam be used in high dust density air,such as with O-SEPA powder separator grinding system. Air dust density can arrive at over 1000g/m3(standard). When using this kind of dust filter, it may not arrange cyclone dust filter as 1st dust filtering. Except cement industry, it can use in metallurgical, chemical industry, machinery and civil boiler etc. waste gas. The material of this series dust filter is normally used terylene needle felt. Allowable applied temperature is less than 120#C. If the temperature of material is improved, you can select to use other filtering material or make down temperature before waste gas enter into dust filter.

This series dust filter is used outdoor. Different chambers and bags come into different specifications. The bag quantity is 32, 64, 96 and 128 bags. The whole series have 33pcs of specifications. The diameter of filtering bag is all 0130mm. The length of filtering bag has 2450mm and 3060mm. This series dust filter can work at positive pressure or minus pressure. Body structure has no any changes. Dust efficiency can meet over 99.9%. Moisture of purified air is less than 100mg/m3(standard). Main technical parameter of this series dust filter refer to attaching table. If this series dust filter is used in high chilled zone where calculated temperature of heating outdoor is less than minus 25°C,it should add heating device and the shell of dust filter need to add insulating layer.

二、构造和工作原理

PPCA/S气箱脉冲袋收尘器由壳体、灰斗、排灰装置、支架和脉冲清灰系统等部分所组成。当含尘气体从进风口进入收尘器后,先碰到进出风口之间的斜隔板,气流便转向流入灰斗,同时气流速度变慢。由于惯性作用,使气体中粗颗粒粉尘直接落入灰斗,起到预收尘的作用。进入灰斗的气流随后折而向上通过内部装有金属骨架的滤袋,粉尘被捕集在滤袋的外表面,净化后的气体进入滤袋室上部的清洁室,汇集到风管排出。壳体用隔板分成若干个Du立的收尘室,按照给定的时间间隔对每个收尘室的过滤收尘室轮流进行清灰。每个收尘室装有一个提升阀,清灰时提升阀关闭,切断通过该收尘室的过滤气流,随即脉冲阀开启,向滤袋内喷入高压空气,以清除滤袋外表面上的粉尘,各收尘室的脉冲喷吹宽度和清灰周期,由专用的清灰程序控制器自动连续进行。

Structure and work principle

This series dust filter is made up of shell, dust hopper, discharge dust device, frame and pulse removing dust system etc. When dust air enter dust filter, first touch middle inclined baffle. Air flow turn to dust hopper and the speed of airflow become slowly.As the inertia, crude material in the air will fall into dust hopper directly and obtain pre-filtering dust. Airflow from dust hopper will pass through metal frame upward, dust is collected on the surface of filtering bag. After purified air enter into up cleaning room, discharge from air outlet pipe. Inlet of type PPCS is arranged on the dust hopper. Airflow enter dust hopper and first touch the baffle of up air inlet. The function is the same as the above. The shell is separated into absolute dust filtering room by baffle. According to the given time interval, clean the dust of every chamber. Every dust chamber is installed one lifting valve. Close lifting valve when removing dust and cut off airflow from dust filter, pulse valve will open and spray high pressure atmosphere to smooth away the dust of filtering bag. The spraying width of dust filter and dust frequency is controlled by special dust program controller automatically and continuously.

三、气箱式脉冲收尘器特点

气箱脉冲清灰袋收尘器的特点是采用分室轮流进行清灰,即所谓离线清灰。当某一室进入喷吹清灰时,过滤气流被切断,避免了喷吹清灰产生粉尘二次飞扬。所以气箱式脉冲袋收尘器能捕集含尘浓度高达1000g/nm3(标)的气体。

The characters of air case pulse bag filter

Air case pulse dust bag filter is used to clean dust in dividing chamber in turn, that is to say, offline clean dust. When one room is spraying dust, filtering air will be cut off and avoid of second scattering of dust. So air case pulse bag filter can collect density of 1000g/m3(standard) air.

四、清灰电气控制装置

1.清灰控制方式

清灰控制方式一般采用定时法,也可采用定阻法。所谓定阻法就是控制滤袋内外侧的压差,当收尘器的差压值达到设定植时(一般为1470Pa),即由差压变送器发出信号,通过电气控制装置,即按既定程序进行逐室清灰。

2.电气控制装置的功能

对多室收尘器集中控制时采用单片机进行集中控制,控制有自动和手动两种方式,当单片机出故障或检修时,可随时切换为手动控制,为便于调试和设备检修并设有机旁控制。

3.清灰电气控制装置到收尘器进线端子的布线设计由选用者负责,接线端子参见清灰电气控制器说明书。

VI. Electric control device of removing dust

1.Dust control way

Dust control way is normally used timing way and given resistance way. The given resistance way can control pressure differential inside and outside filtering bag. When dust filter is to preset valve(normally 1470Pa), pressure differential transformer will send a signal through electric control device. Clean the dust according to regulated program.

2.Electric control device

Many chambers dust filter is used single PLC program controller with centralized control. Control way has automatic control and manual control. When single PLC is something wrong or repairing, change it into manual control at any time. In consideration of commissioning and equipment repayment, it has no local control.

3.The wire arrangement of inlet terminal from dust electric control device to dust filter is selected by the customer. Terminal connection figure refer to operation instructions of electric controller.

五、收尘器系统组成及供货

1、收尘器本体包括壳体、灰斗、滤袋装置进风管、排灰装置和脉冲喷吹系统(包括脉冲阀、管道、阀门、气源三连体和储气罐等)。

2、收尘器配备有清灰电气控制装置,一般按定时清灰控制。如用户要求按定时控制,定货时应注明,其定阻控制的差压计、差压指示报警仪以及其他仪表等的费用要另行计算。

3、收尘器卸灰装置根据用户需要配置。

4、用户要更换滤布来适应其它的特殊要求。如用于高寒地区要增加采暖系统,可直接在订货时说明。

5、收尘器根据不同规格,可以是整机发运,或以解体形式发运,其基础设计由选用者负责。

6、PPCA/S气箱脉冲袋收尘器由制造商提供设备使用和安装说明书

V .Composition and supply scope of dust filter

The body of dust filter is including shell, dust hopper, filtering and device, inlet and outlet pipe, pulse spray¬ing system(include pulse valve, pipe, valve, three connections of air source and air tank etc.)

Dust filter is assorted with removing dust electric control device, normally it use timing dust control. If the customer ask to use given resistance, note it when placing an order. Pressure differential, alarming meter and other instrument will be calculated in another.

Discharge device of dust filter is fitted according to the customer’s requirement.

The customer request to change filtering cloth to meet other special request. For example, high chilled zone should add heating system. It may note in the order.

Dust filter can be shipped in the whole or in partial according to different specifications. The foundation is designed by the customer.

The manufacturer should supply operation and installation instructions.

PPC32/PPC64型气箱式脉冲袋收尘器技术性能表

|

技术参数//型号 |

PPC32-3 |

PPC32-4 |

PPC32-5 |

PPC32-6 |

PPC64-4 |

PPC64-5 |

PPC64-6 |

PPC64-7 |

PPC64-8 |

|

|

处理风量(m2/h) |

6900 |

8030 |

11150 |

13390 |

17800 |

22300 |

26700 |

31200 |

35700 |

|

|

过滤风速(m/min) |

1.2-2.0(根据不同的扬尘点选取不同的净过滤风速) |

|||||||||

|

总过滤面积(m2) |

93 |

124 |

155 |

186 |

248 |

310 |

372 |

434 |

496 |

|

|

净过滤面积(m2) |

62 |

93 |

124 |

155 |

186 |

248 |

310 |

372 |

434 |

|

|

收尘器室数(个) |

2 |

4 |

5 |

6 |

4 |

5 |

6 |

7 |

8 |

|

|

滤袋总数(个) |

96 |

128 |

160 |

192 |

256 |

320 |

384 |

448 |

512 |

|

|

收尘器阻力(Pa) |

1470-1770 |

|||||||||

|

进口气体含尘浓度(g/m3标) |

< 200 |

< 1000 |

|

|||||||

|

出口气体含尘浓度(g/m3标) |

< 0.1 |

|

||||||||

|

收尘器气承受负压(Pa) |

5000 |

|

||||||||

|

清 灰 |

压力(Pa) |

(5-7)X1000 |

||||||||

|

压缩空气 |

耗气量 |

0.27 |

0.37 |

0.46 |

0.55 |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

|

|

(m3/min标) |

|||||||||

|

脉冲阀 |

数量(个) |

3 |

4 |

5 |

6 |

4 |

5 |

6 |

7 |

8 |

|

(带电磁阀) |

规格(英寸) |

1.5 |

2.5 |

|||||||

|

提升阀 |

数量(个) |

3 |

4 |

5 |

6 |

4 |

5 |

6 |

7 |

8 |

|

(带汽缸) |

规格(mm) |

提升阀直径Ø460汽缸直径Ø63 |

提升阀直径Ø595汽缸直径Ø100 |

|||||||

|

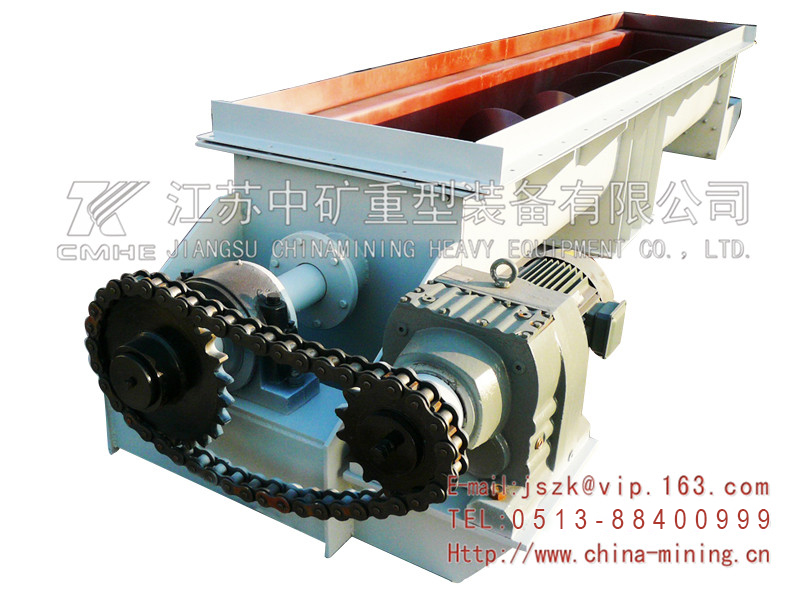

刚性叶轮给料机 |

下料口300X300mm高度150m转速30.31r/min减速电机功率1.1KW产量24m3/h |

|||||||||

|

螺旋输送机 |

规格 |

|

直径Ø300产量30m3/h(填充率Ø=0.7) |

|||||||

|

减速电机 |

|

型号XWD2.2--5--1/43.功率2.2KW |

||||||||

|

空气输送斜槽 |

|

|

||||||||

|

清灰程序控制器 |

输入和输出电压均为220V,控制器由制造厂配套供应,详细资料参看控制器的说明书 |

|||||||||

|

滤袋规格和材质 |

直径X长度Ø130X2450mm,涤纶针刺毡重量450g/m3,使用温度120度 |

|||||||||

|

保温层面积(m2) |

26.5 |

34 |

41 |

48.5 |

70 |

94 |

118 |

142 |

166 |

|

|

设备总量 |

2400 |

3400 |

4400 |

5400 |

6900 |

8300 |

9700 |

11100 |

12500 |

|

|

(约值,不包括保温层) |

||||||||||

|

(kg) |

||||||||||

PPC96型气箱式脉冲袋收尘器技术性能表

|

技术参数//型号 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

PPC96 |

|

|

-4 |

-5 |

-6 |

-7 |

-8 |

-9 |

-2X5 |

-2X6 |

-2X7 |

-2X8 |

-2X9 |

-2X10 |

||

|

处理风量(m2/h) |

26800 |

33400 |

40100 |

46800 |

53510 |

60100 |

66900 |

80700 |

94100 |

107600 |

121000 |

134500 |

|

|

过滤风速(m/min) |

1.2-2.0(根据不同的扬尘点选取不同的净过滤风速) |

||||||||||||

|

总过滤面积(m2) |

372 |

465 |

557 |

650 |

744 |

836 |

929 |

1121 |

1308 |

1494 |

1681 |

1868 |

|

|

净过滤面积(m2) |

279 |

372 |

465 |

557 |

657 |

744 |

836 |

1028 |

1215 |

1401 |

1588 |

1775 |

|

|

收尘器室数(个) |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

|

|

滤袋总数(个) |

384 |

480 |

576 |

672 |

768 |

864 |

960 |

1152 |

1344 |

1536 |

1728 |

1920 |

|

|

收尘器阻力(Pa) |

1470-1770 |

||||||||||||

|

进口气体含尘浓度(g/m3标) |

< 1300 |

||||||||||||

|

出口气体含尘浓度(g/m3标) |

< 0.1 |

||||||||||||

|

收尘器气承受负压(Pa) |

< 5000 |

||||||||||||

|

清 灰 |

压力(Pa) |

(5-7)X1000 |

|||||||||||

|

压缩空气 |

耗气量 |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

2.7 |

3 |

3.4 |

4.2 |

4.8 |

5.4 |

6 |

|

|

(m3/min标) |

||||||||||||

|

脉冲阀 |

数量(个) |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

|

(带电磁阀) |

规格(英寸) |

2.5 |

|||||||||||

|

提升阀 |

数量(个) |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

|

(带汽缸) |

规格(mm) |

提升阀直径Ø725汽缸直径Ø100 |

|||||||||||

|

刚性叶轮给料机 |

下料口400X400mm转速22.5r/min |

下料口350X350mm转速24.63r/min |

|||||||||||

|

减速电机功率1.5KW产量38m3/h |

减速电机功率1.5KW产量30m3/h |

||||||||||||

|

螺旋输送机 |

规格 |

Ø400mm产量38m3/h |

Ø300mm2台每台产量30m3/h |

||||||||||

|

减速电机 |

型号XWD5.5--5--1/59.功率55KW |

型号XWD2.2--5--1/43.功率2.2KW |

|||||||||||

|

空气输送斜槽 |

|

||||||||||||

|

清灰程序控制器 |

输入和输出电压均为220V,控制器由制造厂配套供应,详细资料参看控制器的说明书 |

||||||||||||

|

滤袋规格和材质 |

直径X长度Ø130X2450mm,涤纶针刺毡重量450g/m3,使用温度120度 |

||||||||||||

|

保温层面积(m2) |

110 |

120 |

130 |

140 |

150 |

160 |

175 |

210 |

215 |

280 |

315 |

350 |

|

|

设备总量 |

8710 |

10100 |

12100 |

14100 |

15700 |

17700 |

21000 |

25200 |

29100 |

33600 |

37800 |

42000 |

|

|

(约值,不包括保温层) |

|||||||||||||

|

(kg) |

|||||||||||||

PPC128型气箱式脉冲袋收尘器技术性能表

|

技术参数//型号 |

PPC |

PPC |

PPC |

PPC |

PPC |

PPC |

PPC |

PPC |

PPCA |

PPC |

PPC |

PPC |

|

|

128-6 |

128-9 |

128-10 |

128-2 |

128-2 |

128-2 |

128-2 |

128-2 |

128-2 |

128-2 |

128-2 |

128-2 |

||

|

|

|

|

X6 |

X7 |

X8 |

X9 |

X10 |

X11 |

X12 |

X13 |

X14 |

||

|

处理风量(m2/h) |

67300 |

100900 |

112100 |

134600 |

157000 |

179400 |

201900 |

224300 |

247600 |

269100 |

291600 |

314000 |

|

|

过滤风速(m/min) |

1.2-2.0(根据不同的扬尘点选取不同的净过滤风速) |

||||||||||||

|

总过滤面积(m2) |

935 |

1402 |

1558 |

1869 |

2181 |

2492 |

2804 |

3115 |

3427 |

3738 |

4050 |

4361 |

|

|

净过滤面积(m2) |

779 |

1246 |

1402 |

1713 |

2025 |

2336 |

2648 |

2959 |

6271 |

3582 |

3894 |

4205 |

|

|

收尘器室数(个) |

6 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

滤袋总数(个) |

768 |

1152 |

1280 |

1536 |

1792 |

2084 |

2304 |

2560 |

2816 |

3072 |

3328 |

3584 |

|

|

收尘器阻力(Pa) |

1470-1770 |

||||||||||||

|

进口气体含尘浓度(g/m3标) |

< 1300 |

||||||||||||

|

出口气体含尘浓度(g/m3标) |

< 0.1 |

||||||||||||

|

收尘器气承受负压(Pa) |

6860 |

||||||||||||

|

清 灰 |

压力(Pa) |

(5-7)X100 |

|||||||||||

|

压缩空气 |

耗气量 |

3.6 |

5.4 |

6 |

7 |

8.3 |

9.5 |

10.7 |

12 |

13.1 |

14.3 |

15.5 |

16.7 |

|

|

(m3/min标) |

||||||||||||

|

脉冲阀 |

数量(个) |

12 |

18 |

20 |

24 |

28 |

32 |

36 |

40 |

44 |

48 |

52 |

56 |

|

(带电磁阀) |

规格(英寸) |

2.5 |

|||||||||||

|

提升阀 |

数量(个) |

6 |

9 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

(带汽缸) |

规格(mm) |

提升阀直径Ø725.汽缸直径Ø100 |

|||||||||||

|

刚性叶轮给料机 |

下料口300X300mm |

|

|||||||||||

|

产量24m3/h功率1.1KW |

|||||||||||||

|

螺旋输送机 |

规格 |

Ø300mm产量21m3/h |

|

||||||||||

|

减速电机 |

型号XWD2.2--5--1/43.功率2.2KW |

|

|||||||||||

|

空气输送斜槽 |

斜槽规格250mm,斜槽所需风量为2.0m3/m3透气层,风压5860pa,风机选量和管道配置选用者负责,如进气口气体含尘浓度小于700g/m3标,应选用螺旋输送机的收尘器。 |

||||||||||||

|

清灰程序控制器 |

输入和输出电压均为220V,控制器由制造厂配套供应,详细资料参看控制器的说明书 |

||||||||||||

|

滤袋规格和材质 |

直径X长度Ø130X2450mm,涤纶针刺毡重量450g/m3,使用温度120度 |

||||||||||||

|

保温层面积(m2) |

125 |

196 |

205 |

323 |

247 |

262 |

277 |

292 |

307 |

322 |

337 |

352 |

|

|

设备总量 |

20100 |

26400 |

28900 |

36600 |

43900 |

50000 |

55400 |

60000 |

65400 |

72000 |

78000 |

84000 |

|

|

(约值,不包括保温层) |

|||||||||||||

|

(kg) |

|||||||||||||