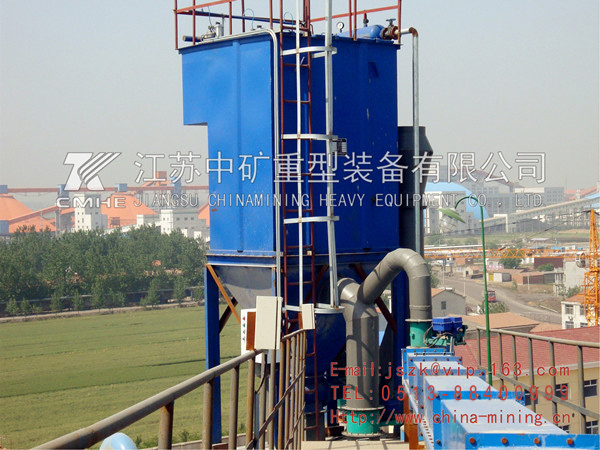

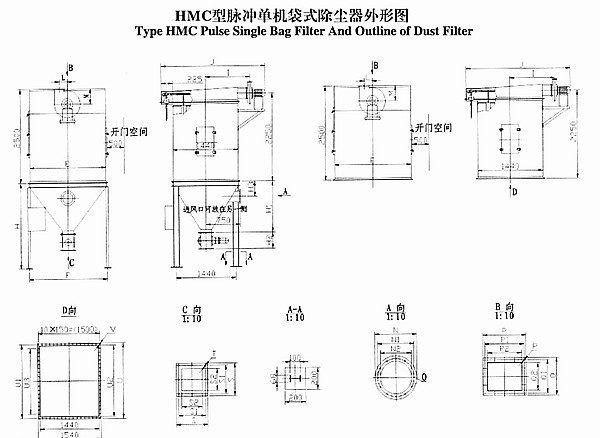

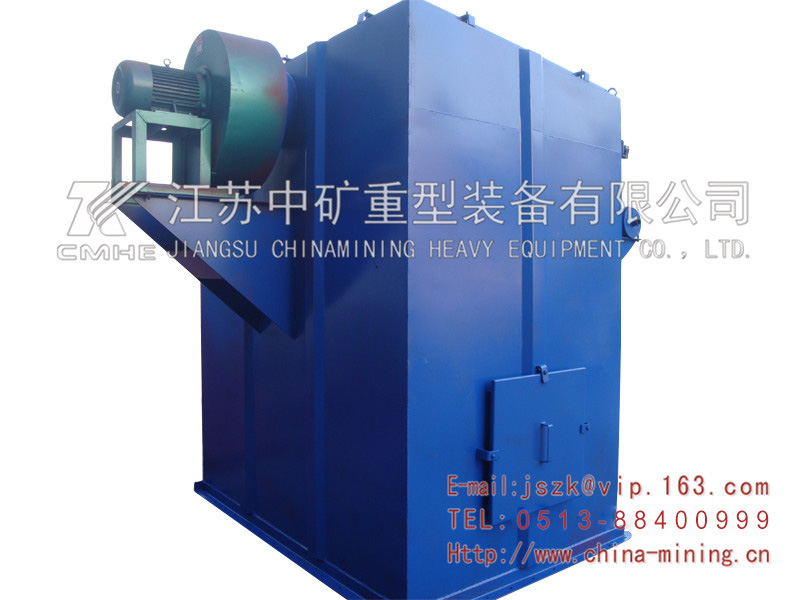

HMC型脉冲单机袋式除尘器

丁宝勤 13906276368(技术)

电话:0513-88400999 传真:0513-88400998 邮箱:jszk@vip.163.com

概述:

HMC型脉冲单机除尘器是我公司消化吸收国内外同类产品经改进后设计而成的小型袋式除尘器。除尘器采用脉冲喷吹的清灰方式。具有清灰效果好、净化效率高、处理风量大、滤袋寿命长、维修工作量小、运行安全可靠等的优点。广泛用于冶金、建材、机械、化工、矿山等各种工矿企业非纤维性粉尘和工业粉尘的除尘净化与物料回收。

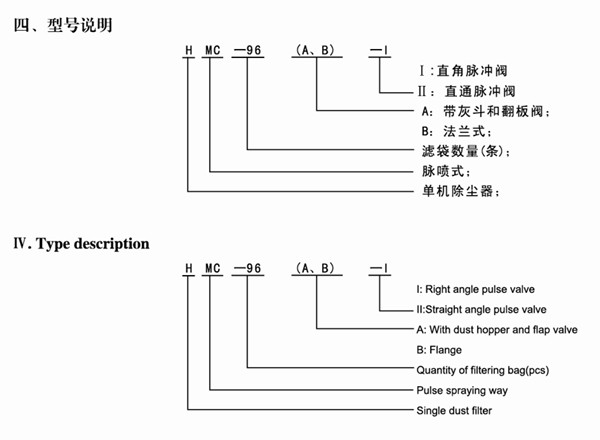

HMC型脉冲单机除尘器共有六个规格,每种规格又可分为标准带灰斗式A型和敞开法兰式(无灰斗)B型二种。其结构主要由过滤室、滤袋、净气室、灰斗、卸灰阀、脉冲喷吹清灰装置、电控箱组成,箱体全部采用焊接结构。检修门用泡沫胶条密封,保证除尘器严密不漏风。

Ⅰ.Brief introduction

Type HMC pulse single bag filter is digested abroad and domestic same product by our company and designed small type bag filter. Bag filter is used pulse and spraying way. It is characterized by good dust efficiency, high clean efficiency, large handle volume, long life of filtering bag, small maintenance and dependable driving. It is widely used in metallurgical, building material, machinery, chemical industry and ore etc. all kinds of ore enterprise etc. non-fibre industry powder to purify dust and material reclaim.

Bag filter have six specifications. Every specification has type A with dust hopper and type B with flange(no dust hopper). The structure is made up of filtering room, filtering bag, purifying chamber, dust hopper, flap valve, flap valve, pulse spraying dust device and electric control cabinet etc. Case body is used welding structure. Inspected door is sealed with foam rubber and guarantee dust filter not leakage.

This product have six specifications, filtering area is from 24 to 84m2. Handle volume is from 1500m3/h to 9000m3/h.Design it especially according to fact need.

构造结构特点:

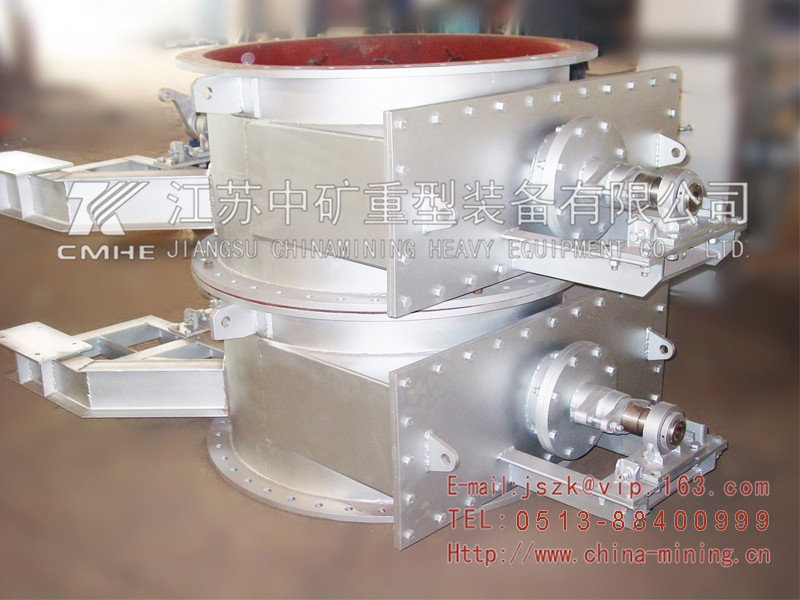

除尘器本体由壳体、滤袋总成、喷吹清灰装置、排灰装置四个部分组成。

壳体部分由上箱体、中箱体、灰斗、进出风口组成。

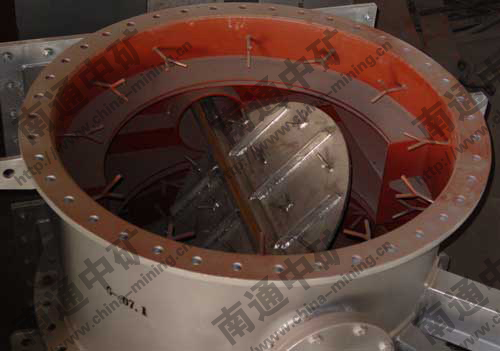

滤袋总成由滤袋、滤袋框架等组成。

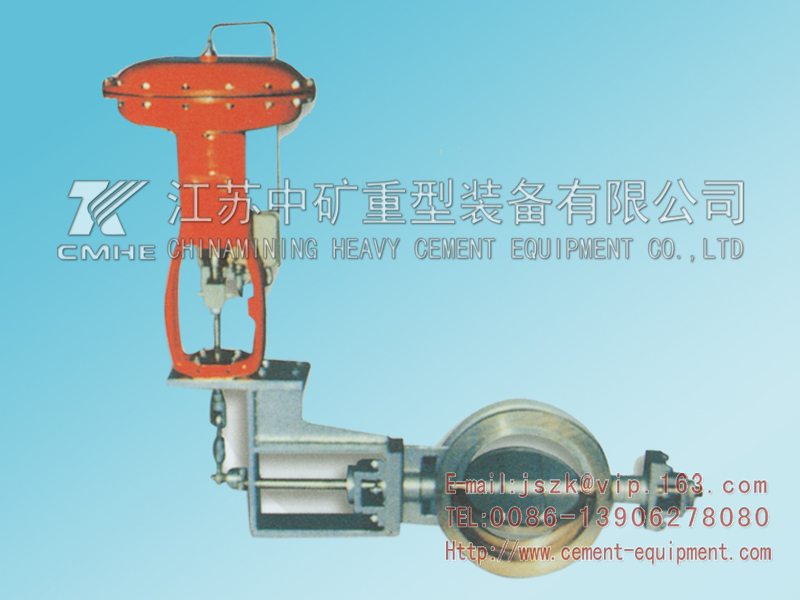

喷吹清灰装置由气包、喷吹管、脉冲阀、电磁控制阀、电控仪等组成。

排灰装置由电机、减速器、螺旋输送机、星形卸料阀组成。

脉冲阀I型采用直角脉冲阀,Ⅱ型采用直通脉冲阀,减少了脉冲阀自身的阻力,是一种较为理想的脉冲喷吹方式。

Ⅱ.Structure features

The body of bag filter is made up of shell, filtering bag assumable, spraying dust device and dust discharge device.

Filtering bag assemble is made up of filtering bag and filtering bag frame etc.

Spraying dust discharge device is made up of gas bag, spraying pipe, pulse valve, electric control valve and electric control meter etc.

Discharge dust device is made up of motor, reducer, screw conveyor and star discharge valve.

Pulse valve type I is used right angle pulse valve, Type II is used right pulse valve and reduce the resistance of pulse valve which is an ideal pulse spraying type.

工作原理:

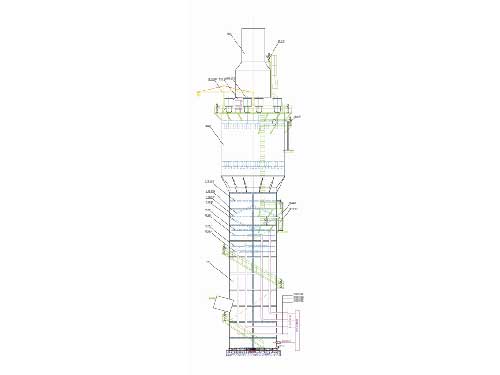

HMC型除尘器的进风口设在灰斗上,当含尘气体从进风口进入灰斗后先碰上进风口的挡板,由于惯性作用,使气体粗颗粒粉尘直接进入灰斗,起到预收尘的作用,进入灰斗的气流随后折而向上通过内部装有金属骨架的滤袋,粉尘被收集在滤袋的外表面,净化后的气体进入滤袋室上部的清洁室,汇集到出风管排出。室内收尘袋分为若干排,按照给定的时间间隔对每排收尘袋进行清灰。当脉冲阀开启时,即向滤袋内喷入高压空气,以清除滤袋表面上的灰尘。各排滤袋的脉冲喷吹宽度和清灰周期,由专用的清灰程序控制器自动连续控制。除尘器的构造和工作原理参见附图。

含尘气体由灰斗(或下部敞开式法兰)进入过滤室,较大颗粒直接落入灰斗或料仓。

Work principle

Inlet of Type HMC dust filter is designed on dust hopper. Dust gas first touch with stopper plate from air inlet to dust hopper. As the interia, crude material in the gas directly will enter into dust hopper and have the effect of pre-dust. Air flow from dust hopper is passed through filtering bag with metal frame. Powder dust is collected on the surface of filtering bag. Purified air enters into cleaning room on the top of filtering bag. Collect outlet pipe and discharge. Dust bag indoor is divided into many rows according to given interval and clean dust of every row filtering bag. When pulse valve is starting, filtering bag is sprayed high pressure atmosphere and smooth away powder dust of filtering bag surface. The width and dust frequency of pulse spraying is controlled by special dust program controller. The structure and work principle of dust filter refer to attaching drawing.

Dust gas enter filtering chamber from dust hopper (or bottom open flange) and crude grain enter into dust hopper or dust silo.

主要技术性能参数 V .Main technical capacity parameter

HMC型脉冲单机袋式除尘器技术性能参数

Technical capacity parameter of type HMC pulse single bag filter

|

型号 |

HMC-32 |

HMC-48 |

HMC-64 |

HMC-80 |

HMC-96 |

HMC-112 |

|

|

性能 |

|||||||

|

处理风量m3/h |

1500-2400 |

2100-3500 |

3500-5000 |

4000-6000 |

5200-7000 |

6000-9000 |

|

|

总过滤面积m2 |

24 |

36 |

48 |

60 |

72 |

84 |

|

|

过滤风速(m/min) |

1.00-1.50 |

1.00-1.50 |

1.00-1.50 |

1.10-1.70 |

1.20-1.70 |

1.20-1.80 |

|

|

滤袋数量(条) |

32 |

48 |

64 |

80 |

96 |

112 |

|

|

入口气体温度(℃) |

≤120 |

||||||

|

除尘器阻力(Pa) |

≤1200 |

||||||

|

进口粉尘浓度(g/m3) |

<200 |

||||||

|

出口排放浓度(mg/m3) |

≤100 |

||||||

|

清灰用压缩空气 |

压力(Pa) |

0.5-0.7 |

|||||

|

耗气量(m3/min) |

0.10 |

0.14 |

0.20 |

0.24 |

0.29 |

0.34 |

|

|

承受负压Pa |

5000 |

||||||

|

脉冲阀数量(个) |

4 |

6 |

8 |

10 |

12 |

14 |

|

|

风机用电机功率(KW) |

1.5 |

3.0 |

3.0 |

5.5 |

5.5 |

7.5 |

|

|

重量 |

A型(带灰斗) |

1350 |

1620 |

1850 |

2360 |

2800 |

3200 |

|

B型(不带灰斗) |

1220 |

1470 |

1670 |

2150 |

2540 |

2880 |

|

HMC型脉冲单机袋式除尘器外部参数及联接尺寸

|

|

HMC— |

HMC— |

HMC— |

HMC— |

HMC— |

HMC— |

型号 |

HMC— |

HMC— |

HMC— |

HMC— |

HMC |

HMC— |

|

代号 |

32 |

48 |

64 |

80 |

96 |

112 |

代号 |

32 |

48 |

64 |

80 |

96 |

112 |

|

E |

760 |

1120 |

1460 |

1820 |

2160 |

2520 |

P1 |

4×65 |

4×80 |

4×80 |

5×71 |

5×71 |

5×79 |

|

F |

828 |

1188 |

1528 |

1888 |

2228 |

2588 |

P2 |

229 |

288 |

288 |

320 |

320 |

360 |

|

H |

1810 |

1810 |

1880 |

2080 |

2230 |

2460 |

R |

14—φ7 |

16—φ7 |

16—φ7 |

20—φ7 |

20—φ7 |

20—φ7 |

|

H1 |

1300 |

1300 |

1300 |

1500 |

1750 |

1980 |

Q |

231 |

306 |

306 |

334 |

334 |

369 |

|

H2 |

310 |

310 |

380 |

380 |

380 |

380 |

Q1 |

3×69 |

4×71 |

4×71 |

5×63 |

5×63 |

5×70 |

|

H3 |

300 |

330 |

400 |

400 |

400 |

430 |

Q2 |

176 |

252 |

252 |

280 |

280 |

315 |

|

I |

986 |

968 |

968 |

988 |

988 |

1000 |

S |

270 |

270 |

330 |

330 |

330 |

330 |

|

J |

2286 |

2396 |

2396 |

2489 |

2489 |

2524 |

S1 |

3×76 |

3×76 |

3×98 |

3×98 |

3×98 |

3×98 |

|

L |

238 |

252 |

252 |

280 |

280 |

315 |

S2 |

180 |

180 |

240 |

240 |

240 |

240 |

|

M |

218.6 |

239 |

244.5 |

265 |

265 |

297.5 |

T |

12—φ11 |

12—φ11 |

12—φ11 |

12—φ11 |

12—φ11 |

12—φ11 |

|

N |

φ300 |

φ350 |

φ400 |

φ450 |

φ450 |

φ450 |

U |

860 |

1220 |

1560 |

1920 |

2260 |

2620 |

|

NI |

φ250 |

φ300 |

φ350 |

φ400 |

φ400 |

φ450 |

U1 |

820 |

1180 |

1520 |

1880 |

2220 |

2580 |

|

N2 |

φ |

φ |

φ |

φ |

φ |

φ |

U2 |

760 |

1120 |

1460 |

1820 |

2160 |

2520 |

|

|

200 |

250 |

300 |

350 |

350 |

400 |

|

|

|

|

|

|

|

|

O |

12—φ11 |

12—φ11 |

12—φ11 |

16—φ11 |

16—φ11 |

16—φ11 |

U3 |

4×150 |

6×150 |

8×150 |

10×150 |

13×150 |

15×150 |

|

P |

283 |

342 |

342 |

374 |

374 |

414 |

V |

32—φ14 |

36—φ14 |

40—φ1 |

44—φ14 |

50—φ14 |

54—φ14 |

订货要求

1、订货时,客户请写清楚规格、型号,同时提供粉尘治理点的工况参数,便于更好地为 客户服务。

2、如客户委托我公司选型设计,应在合同中注明,具体事宜与我公司营销部联系。

3、设备供应范围:

a.主机设备:以进出口法兰为界,下部以灰斗卸灰法兰为界,气路部分以分气箱进气口为界;

b.附件设备:定时清灰控制器;

c.随机文件:产品说明书、安装图、产品合格证;

d.本公司遵循不断完善产品性能的原则,对产品规格、性能不断改进,或许难以及时通知阁下

工程技术参数与样本不符,以随机技术文件为准。

Ⅶ.Order request

When placing an order, the customer should write the specification, type and work condition parameter at the same time of dust manage. Provide good service for the customer conveniently.

If the customer consigns us to select the design, it will mark in the contract. The details will contact with our sales department.

Supply scope of equipment:

Main equipment: The flange of inlet and outlet is the boundary. Dust discharge flange is bottom boundary.

Attaching equipment: Time clean dust controller.

Random document: Operation manual, installation drawing and quality certificate.

Our company is on the basis of product capacity. If specification and capacity is improved, we will inform the customer. If the technical parameter is not complied with the sample, the customer should be on the basis of random technical document.

.jpg)