辊压机

周先生:13906278080

电话:0513-88400999 传真:0513-88400998 邮箱:13906278080@139.com

辊压机是本公司承接的新型水泥节能粉磨设备,能全部或部分替代能耗高的球磨机系统,并且具 有耗材少、噪音低的功能,适用于新厂建设,也可用于老厂技术改造。选用该设备后,可使球磨机系统产量提高40—100%,经过挤压后的物料料饼中0.08mm细料占20-55%,小于2mm占65-85%,小颗粒的内 部结构因受挤压而充满许多微小裂纹,易磨性大为改善。辊面采用热堆焊,耐磨层维修更为方便。

本公司多年来不断追求改进、创新,已形成了一套成熟的设备技术和完整的粉磨工艺,主要特点:

1、辑面堆焊采用进口焊机和先进的耐磨焊条及工艺技术进行焊接,使用寿命大幅度提高。

2、利用航空技术生产的液压油缸性能可靠。

3、自控系统采用触摸屏动态显示。自动控制配有专家诊断系统,故障自动解除,控制可靠。

4、配套打散分级机,V型分级机和回转式打散分级机。分选率达90%。

The roll squeezer is a new type energy-saving cement powder mill firstly manufactured by our company. It can completely or partially replace the ball mill with high energy consumption. It is featured by few consumables and low noise. It can be used for new factory construction and for old factory technical reconstruction. This equipment can help the ball mill system improve the output by 40—100%.

The squeezed material pie has 20~55% tiny particles of 0.08mm and 65—85% particles smaller than 2mm. The small particles are full of tiny cracks for being squeezed, so the grindability is greatly improved.

The roll surface is welded in the hot build-up way so that the maintenance of the wear-resistant layer is more convenient.

Our company has been pursuing reform and innovation for years, and has formed a set of mature technologies and complete grinding techniques. The main characteristics are as follows:

1. The build-up welding on the roll surface is done by the imported welder and with the internationally advanced wear-resistant welding rods and techniques. The service life increases greatly.

2.The hydraulic cylinder produced by using aeronautical technology has a reliable performance.

3.The automatic control system has a touch screen. It has a professional diagnosis system so that the trouble can be removed automatically. The control is reliable.

辊压机技术参数 Technique parameter

辊压机技术参数Technical parameter | ||||||||||

型号 Model | 辊径 Diameter | 辊宽 Width | 喂 料粒度上限 Max material granularity | 喂 料温度上限 Max material temperature | 预粉碎能力 Expected grinding capacity | 主电动机Main motor | 整机 重量 Unit Weight | |||

熟料 Clinker(t/h) | 生料Raw material (t/h) | 型号 Model | 功率Power(KW) | 电压Voltage (v) | ||||||

G200-180 | Φ2000 | 1800 | 80 | ≤100 | 920~1150 | 920 ~1250 | YRKK630 | 1800x2 | 6000〜10000 | 340 |

G200-120 | Φ2000 | 1200 | 75 | ≤100 | 730~850 | 750~1000 | YRKK560 | 1400x2 | 300 | |

G180-120 | Φ1800 | 1200 | 75 | ≤100 | 650~760 | 660~780 | YRKK560 | 1250x2 | 225 | |

G170-100 | Φ1700 | 1000 | 70 | ≤100 | 580~670 | 600~680 | YRKK500 | 900x2 | 190 | |

G160-140 | Φ1600 | 1400 | 65 | ≤100 | 600~720 | 650~760 | YRKK560 | 1120x2 | 210 | |

G150-100 | ΦI 500 | 100 | 60 | ≤150 | 460~500 | 485~520 | YRKK500 | 710x2 | 178 | |

G140-80 | Φ1400 | 800 | 55 | ≤150 | 320~360 | 330~390 | YRKK560 | 630x2 | 115 | |

G140-70 | Φ1400 | 700 | 55 | ≤150 | 240~300 | 260~320 | YRKK500 | 500x2 | 110 | |

G120-50 | Φ1200 | 500 | 50 | ≤150 | 110~175 | 175~190 | Y355L | 250x2 | 380 | 65 |

G120-45 | Φ1200 | 450 | 50 | ≤150 | 95~150 | 110~175 | Y355L | 220x2 | 62 | |

G100-35 | Φ1000 | 350 | 45 | ≤80 | 45~60 | 50 ~ 70 | Y355M | 185x2 | 30 | |

G100-30 | Φ1000 | 300 | 45 | ≤80 | 40~50 | 45 ~65 | Y355M | 160x2 | 30 | |

G80-25 | Φ800 | 250 | 40 | ≤80 | 20~30 | 25 ~ 35 | Y315S | 90x2 | 23 | |

工作原理

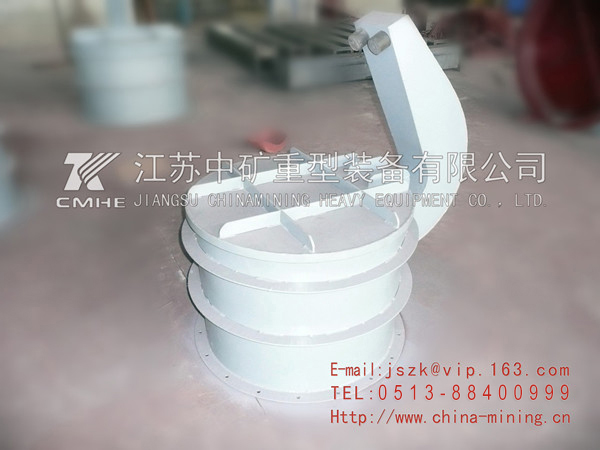

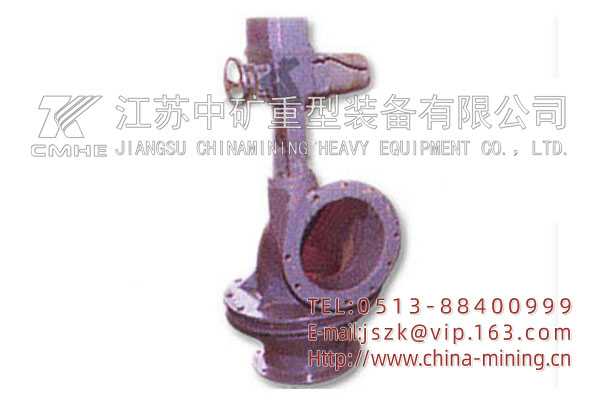

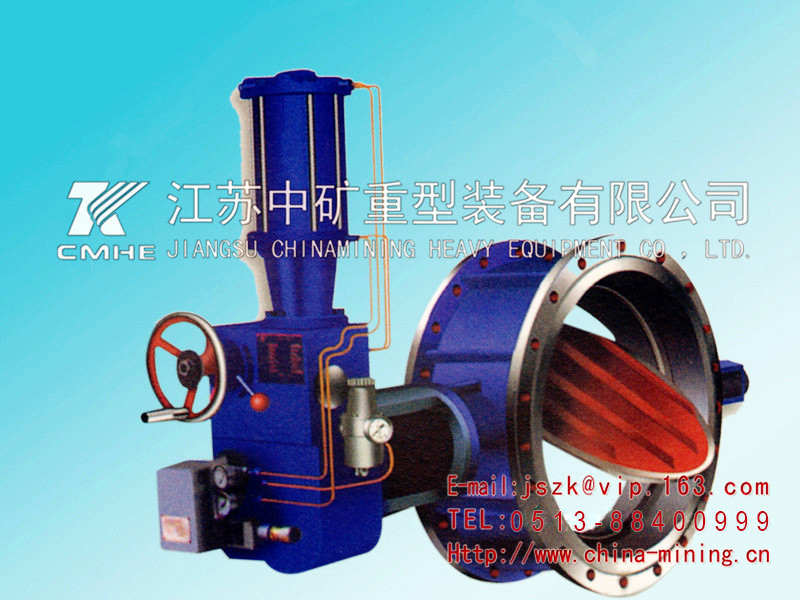

辊压机是根据料床粉磨原理设计而成,其主要特征是:高压、满速、满料、料床粉碎。辊压机由两个相向同步转动的挤压辊组成,一个为固定辊,一个为活动辊。

物料从两辊上方给入,被挤压辊连续带入辊间,受到100-150MPa的高压作用后,变成密实的料饼从机下排出。排出的料饼,除含有一定比例的细粒成品外。在非成品颗粒的内部,产生大量裂纹,改善了物料的易磨性,且在进一步粉碎过程中,可较大地降低粉磨能耗。

物料通过磨辊主要分为三个阶段:满料密集、层压粉碎、结团排料阶段。

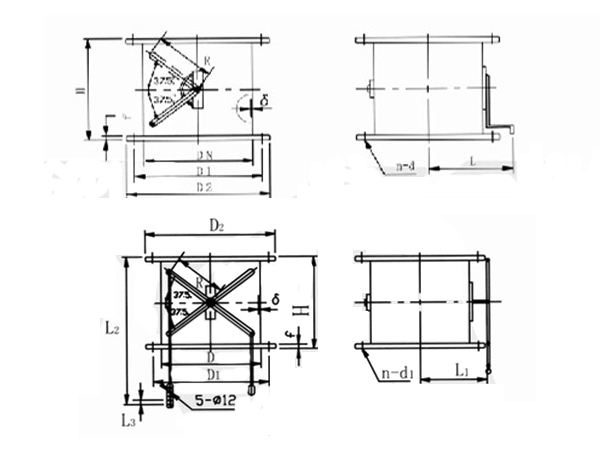

主要结构

辊压机由机架、两个辊系、传动装置、扭矩支承、辊罩、进料装置、液压(加压)系统、主轴承润滑系统、干油润滑系统、电气系统等部份组成。