立磨

周先生:13906278080

电话:0513-88400999 传真:0513-88400998 邮箱:13906278080@139.com

一、总论

立磨属于辊式磨的一种,按照要求可以配置2, 3或者4个磨辊。每一个磨辊,它都是由固定的摇臂、安装摇臂的支架,以及液压系统组成了粉磨的动力单元。此动力单元为整体式或者一个标准组件,它可在磨盘周围布置成二组分、三组分或者四组分。

I. Overview

SH vertical mill is one of the roll mills. It can be equipped with 2, 3 or 4 grinding rolls. Each grinding roller is composed of fixed rock arms, frame and hydraulic pressure system, which is the drive unit. This drive unit is an integral or standard part. It can be mounted around the grinder to be two-component, three-component or four-component.

二、工作原理

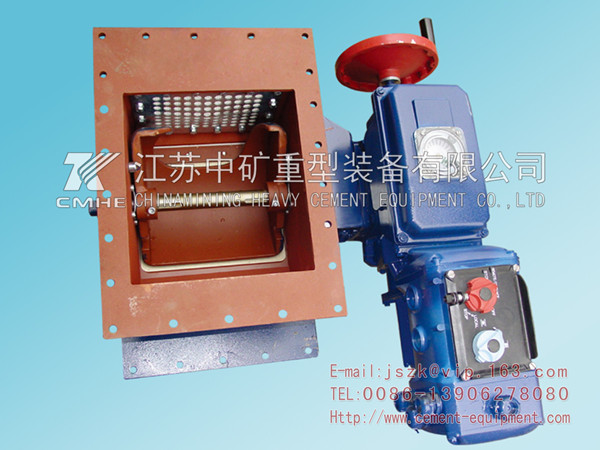

原料通过自动进料装置进入到下料管,下料管是透过分离器的侧面或中间进入到磨机内部的。物料借助于重力和气流的冲击作用而落到磨盘中央。磨盘牢固的与减速机相连,以恒速旋转。磨盘的恒速旋转将粉磨物料均匀的水平分布在磨盘的衬板上,液压系统的强大压力通过摇臂传递到磨辊,并由自动控制系统保证磨辊能保持恒定压力,斜锥式的磨辊结构能够咬住物料,在与磨盘相对运动的过程中 将物料碾碎,并在碾压与磨擦运动的共同作用下将物料碼成粉末。在离心力的作用下,被磨碎的粉料 向磨盘边缘甩出,与进入磨机的高速热气流混合并进行充分的热交换,水份被迅速蒸发,跟随热气流 上升的粉料水份已不超过1%,不断进入磨机中部的物料也在离心力的作用下不断向磨辊的碾压轨迹区 运动填补被甩出物料的空间,行成物料顺序流动。被高速气流带动上升的粉料进入分离器进行分选,分选出的合格粉料被送入收尘器回收入库,不合格的粉料被分离器转子叶片甩出与外静叶片碰撞,使其动能衰减,落回磨盘中进行再粉磨。形成了粉磨过程的动态循环作业。

II. Working principle

The raw material goes into the tremie pipe through the automatic feeder. The tremie pipe extends into the inside of the mill through the concentrator’ s side or center. The material drops on the center of the grinder with the help of the force of gravity and the gas impact. The grinder is firmly connected to the speed reducer, spinning at a constant speed. The grinder’ s constant speed spinning scatters the material evenly on the plate of the grinder. The strong pressure of the hydraulic pressure system is transmitted to the grinding roll through the rock arms. The automatic control system ensures the constant pressure of the roller. The bevel roller structure helps to seize materials and crushes the materials in the relative motion to the grinder. The material is ground into powder with the forces of roll and friction. By means of centrifugal force, the ground powder is drawn out to the edge of the grinder. Then the material is mixed with the high speed hot air current and has fully heat exchange so that the water is instantly evaporated. The water in the powder rising with the hot air stream is not more than 1%. The material constantly fed into the mill moves to the rolling track of the grinding roll by the force of centrifugal force in order to replace the drawn out material. Thus, the material can flow in order. The powder rising with the high speed air stream goes into the concentrator, and the qualified powder is centrifuged into the dust collector, the unqualified is ejected out by the rotor blades to collide with the outer still blades and drops into the grinder to get ground again. Then the grinding is repeated.

三、特点

◎噪音低 ◎单位能耗低 ◎控制反应迅速

◎从启动到停机,振动很小 ◎适应性强

◎占地面积小 ◎调节简便 ◎干法粉磨能力极佳

◎维修方便(不必拆除磨机便可更换磨损件) ◎可对各种不同物料进行粉磨

III. Characteristics

◎Low noise ©Low unit energy consumption ◎ Quick control reaction ◎Tiny vibration from start to stop ©Good adaptability

◎Small body,Convenient adjustment ◎ Excellent dry grinding

©Convenient maintenance (part replacing without dismantling) ©All different kinds of materials to be ground

SHMS矿渣立磨标准参数表

SHMS Slag Vertical Mill Standard Parameters

|

磨机主要参数及能力Main Parameters and Capacities |

|||||||

|

磨机型号Model |

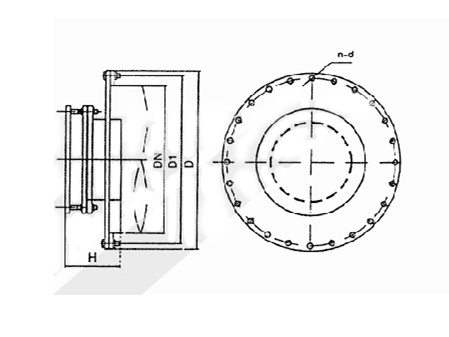

磨盘直径 Grinder Diameter (mm) |

磨盘轨道直径 Grinder Track Diameter d(mm) |

磨辊平均直径 Roll Average Diameter(mm) |

磨辊数 Roll Number |

磨盘转数 Rotation Number(rpm) |

广能力 Capacity (t/h) |

^机功率Power (kW) |

|

SHMS50.41 |

5000 |

4266 |

2360 |

4(2+2) |

25.9 |

120 |

3500 |

|

SHMS46.41 |

4600 |

3908 |

2240 |

4(2+2) |

27.0 |

100 |

3150 |

|

SHMS43.41 |

4300 |

3608 |

2120 |

4(2+2) |

27.9 |

85 |

2800 |

|

SHMS40.41 |

4000 |

3411 |

1900 |

4(2+2) |

29.0 |

75 |

2000 |

|

SHMS35.41 |

3500 |

2932 |

1800 |

4(2+2) |

30.9 |

60 |

1800 |

|

SHMS34.41 |

3400 |

2868 |

1700 |

4(2+2) |

31.4 |

50 |

1600 |

|

SHMS32.41 |

3200 |

2694 |

1600 |

4(2+2) |

32.4 |

45 |

1600 |

|

SHMS30.41 |

3000 |

2520 |

1500 |

4(2+2) |

33.4 |

40 |

1250 |

|

SHMS28.41 |

2800 |

2346 |

1400 |

4(2+2) |

34.6 |

35 |

1000 |

磨机能力评价基准:

(1)原料中等易磨性(MFs) = 0.9〜1.0;

(2)原料水分15%;

(3)精粉粒度:4200 -4500cm2/g ;

(4)精分水分0.5~1.0%。

Note:

Mill capacity standard

(1) Medium grindability of raw material

(2) Material water content 15%

(3) Powder granularity

(4) Powder water content

SHCM标准烟煤立磨技术参数(无烟煤立磨单独讨论)

|

磨机主要参数及能力Main Parameters and Capacities |

||||||

|

磨机型号Model |

磨盘直径Grinder Diameter (mm) |

磨辊平均直径 Roll Average Diameter(mm) |

磨辊数 Roll Number |

磨盘转数 Rotation Number(rpm) |

标准能力 Standard CapacityQ(t/hf |

装机功率Power (kW) |

|

SHCM35.30 |

3500 |

1900 |

3 |

30.9 |

70 |

1400 |

|

SHCM30.30 |

3000 |

1900 |

3 |

33.4 |

65 |

1250 |

|

SHCM28.30 |

2800 |

1750 |

3 |

34.6 |

55 |

1000 |

|

SHCM26.30 |

2600 |

1600 |

3 |

35.9 |

45 |

810 |

|

SHCM23.30 |

2300 |

1450 |

3 |

38.2 |

35 |

640 |

|

SHCM22.30 |

2200 |

1400 |

3 |

39 |

30 |

590 |

|

SHCM20.30 |

2000 |

1250 |

3 |

40.9 |

20 |

430 |

|

SHCM16.30 |

1600 |

1000 |

3 |

45.8 |

12 |

250 |

备注:

磨机能力评价基准:

(1) 原料中等易磨性HGI= 55-60;

(2) 原料水分10%;

(3) 精粉粒度:80mmR3%;

(4) 精分水分0.5~1.0%。

Note:

Mill capacity standard

(1) Medium grindability of raw material

(2) Material water content 10%

(3) Powder granularity

(4) Powder water content

SHRM生料立磨技术参数表

SHRM Raw Material Vertical Mill Technical Parameters

|

磨机主要参数及能力Main Parameters and Capacities |

||||||||

|

磨机型号Model |

磨盘直径Grinder |

辱襌平埤.直径 Roll Average Diameter(mm) |

磨辑数 Roll Number |

磨盘转数 Rotation Number(rpm) |

装机功率Power (kW) |

标准能力 Standard CapacityQ(t/h) |

保证能力 Guaranteed Capacity Q(t/h) |

配备水泥Cement |

|

SHRM13.20 |

1300 |

1100 |

2 |

43 |

200 |

25 |

20 |

|

|

SHRM16.20 |

1600 |

1180 |

2 |

45.77 |

200 |

26.4 |

22 |

|

|

SHRM18.30 |

1800 |

1120 |

3 |

43.16 |

330 |

43.9 |

37 |

|

|

SHRM19.30 |

1900 |

1180 |

3 |

42.01 |

380 |

50.4 |

43 |

|

|

SHRM20.30 |

2000 |

1250 |

3 |

40.94 |

430 |

57.8 |

49 |

|

|

SHRM22.30 |

2200 |

1400 |

3 |

39.04 |

580 |

77 |

65 |

|

|

SHRM23.30 |

2300 |

1450 |

3 |

38.18 |

630 |

83.5 |

71 |

|

|

SHRM26.30 |

2600 |

1600 |

3 |

35.91 |

810 |

108.1 |

92 |

|

|

SHRM30.30 |

3000 |

1700 |

3 |

33.43 |

950 |

126.9 |

108 |

|

|

SHRM30.40 |

3000 |

1400 |

4 |

33.43 |

1100 |

160.8 |

137 |

-2000 |

|

SHRM32.40 |

3200 |

1400 |

4 |

32.37 |

1200 |

168.7 |

143 |

|

|

SHRM32.40 |

3200 |

1500 |

4 |

32.37 |

1300 |

188.7 |

160 |

|

|

SHRM34.40 |

3400 |

1500 |

4 |

31.4 |

1400 |

197.3 |

168 |

2000 |

|

SHRM36.42 |

3600 |

1700 |

4 |

30.52 |

1600 |

231.7 |

197 |

2500、3000 |

|

SHRM38.42 |

3800 |

1700 |

4 |

29.7 |

1900 |

266 |

226 |

|

|

SHRM40.42 |

4000 |

1800 |

4 |

28.95 |

2100 |

307 |

261 |

3500、4000 |

|

SHRM43.42 |

4300 |

1900 |

4 |

27.92 |

2500 |

357.4 |

304 |

|

|

SHRM46.42 |

4600 |

2060 |

4 |

27 |

3100 |

436.2 |

371 |

4500 |

|

SHRM48.41 |

4800 |

1900 |

4 |

26.43 |

2700 |

386.5 |

329 |

|

|

SHRM48.42 |

4800 |

2060 |

4 |

26.43 |

3100 |

449.8 |

382 |

4500、5000 |

|

SHRM50.41 |

5000 |

2240 |

4 |

25.89 |

3600 |

516.3 |

439 |

|

|

SHRM53.41 |

5300 |

2360 |

4 |

25.15 |

4200 |

595.6 |

506 |

-6000 |

|

SHRM53.42 |

5300 |

2500 |

4 |

25.15 |

4400 |

630.6 |

536 |

6000 ~ 7000 |

|

SHRM56.42 |

5600 |

2500 |

4 |

24.47 |

4600 |

655.7 |

557 |

|

备注:

磨机选型基准:

(1) 料中等易磨性(MF) = 0.9〜1.0;

(2) (2)原料水分7%;

(3) 精粉粒度80 m mR 12-15 %;

(4) 精粉水分0.5 ~ 1.0 % ;

(5) 以上条件同样适合石灰石粉磨,具体选型根据物料特性而定。

Note:

Mill capacity standard

(1) Medium grindability of raw material

(2) Material water content 15%

(3) Powder granularity

(4) Powder water content

(5) The above conditions are also suitable for limestone mill. The model depends on the material.